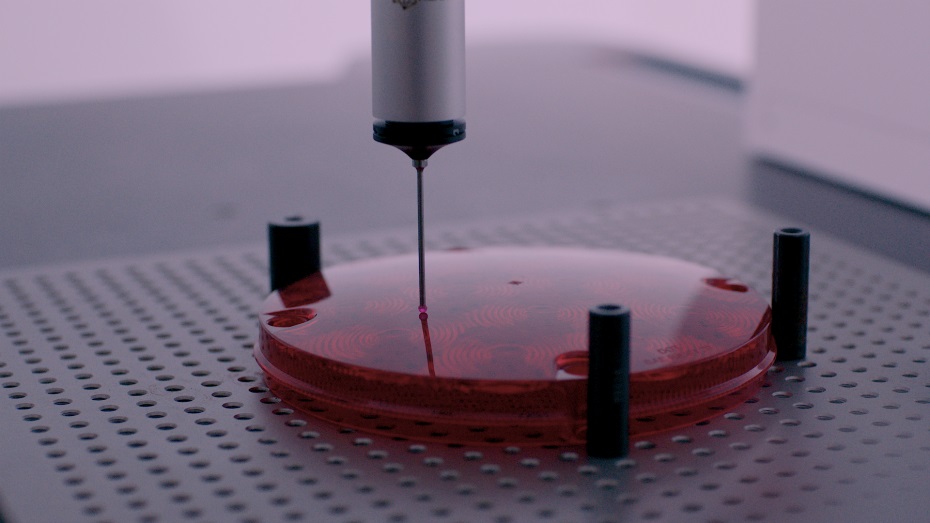

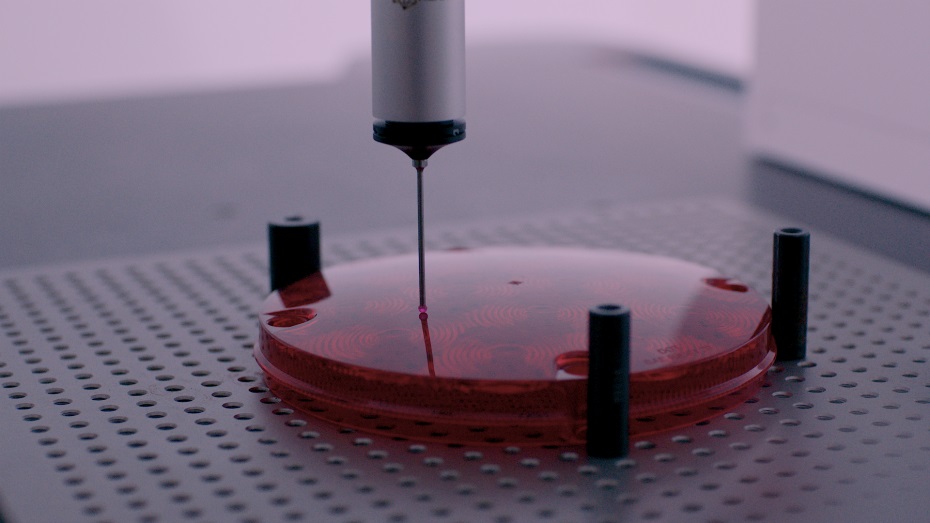

FordaLite has multiple standard assembly lines, equipped with hot plate welding machines, friction welding machines, watertight/airtight testing machines, and automatic terminal testing machines.

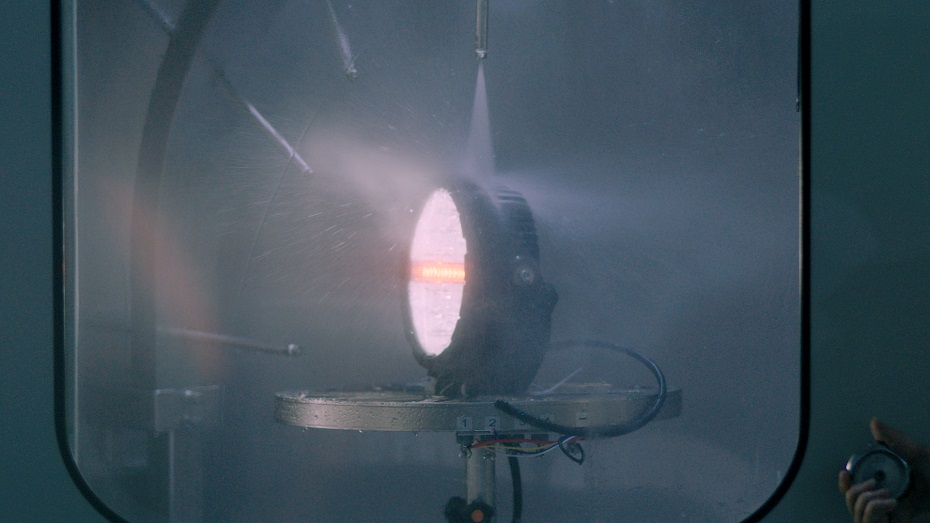

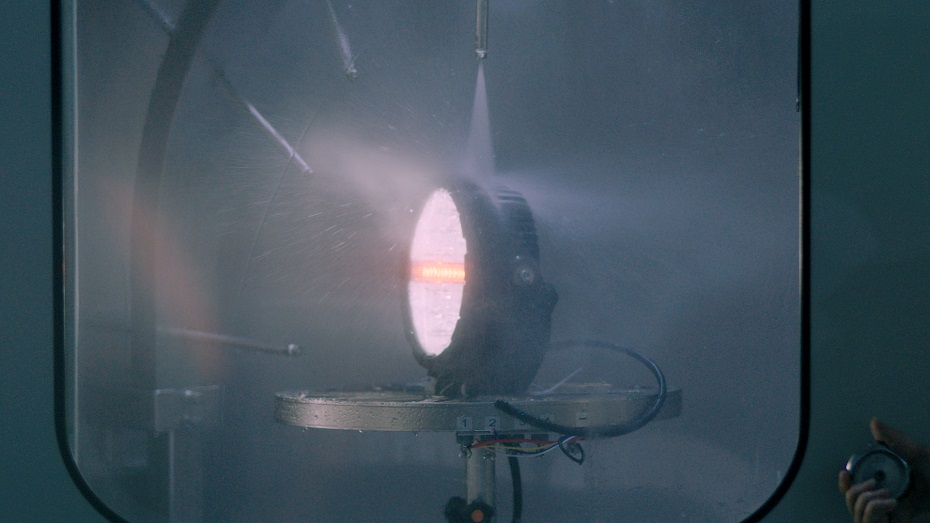

The company is equipped with automotive light testing equipment that can be used to verify design and conduct reliability tests. FordaLite has become an industry leader able to carry out full environmental testing validation in-house including vibration performance, water tightness, high and low temperature, dust prevention, corrosion, ESD and optical performance testing.

Equipped with intelligent and automatic equipment, the strict production management system, ensures that every production and manufacturing process strives for perfection.

The injection workshop is equipped with a complete centralized feeding system, different tonnage injection molding machines, and high-performance manipulators, to conduct independent manufacturing of various single and double color outer lens and inner lens.

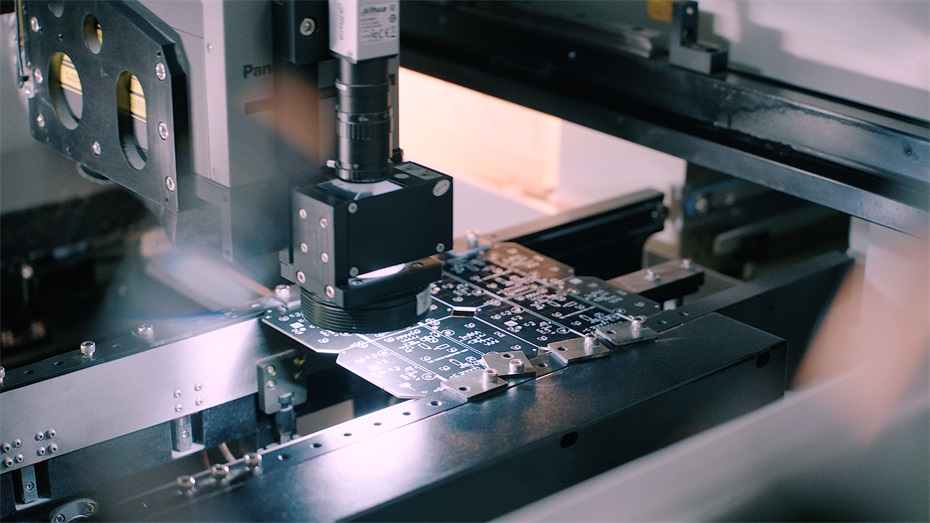

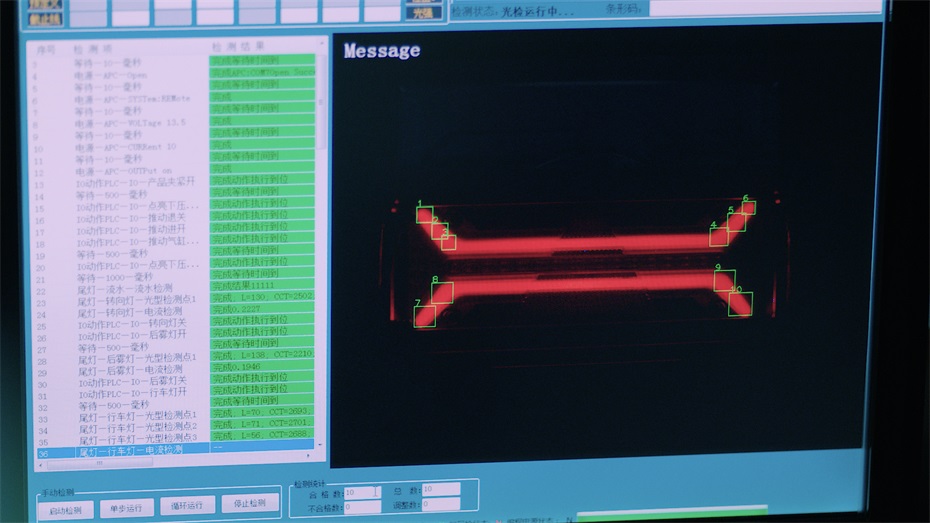

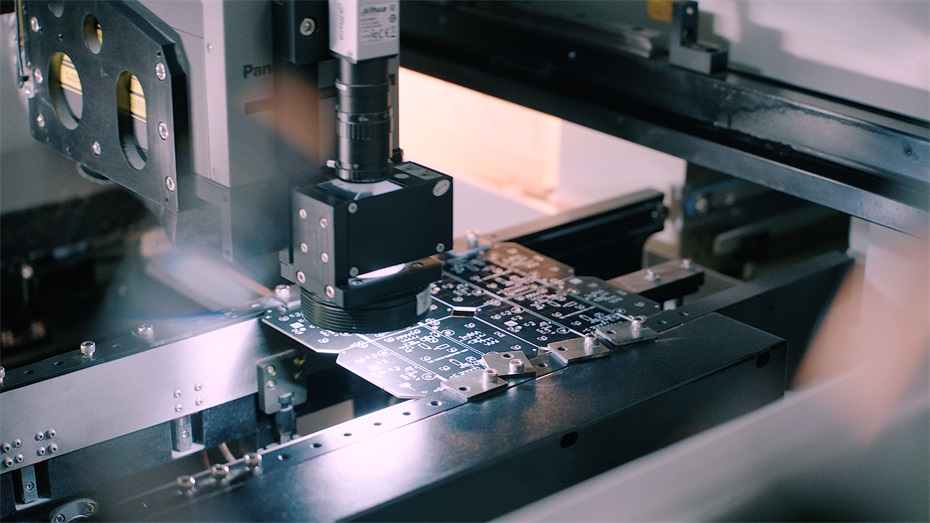

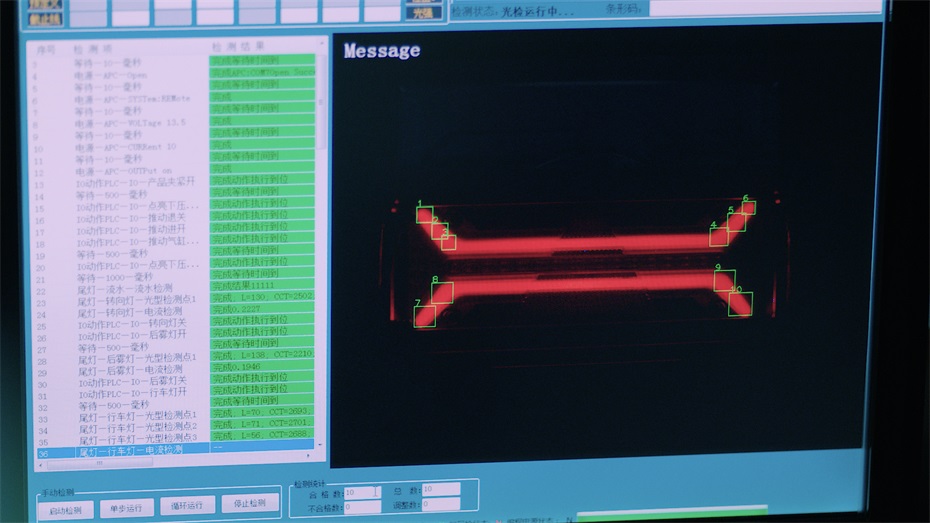

The SMT workshop has introduced an enterprise-level MES information management system that has made management more intelligent. The QR code laser engraving machine, automatic SMT component placement system, and AOI automatic optical detection system ensure each product’s stability and traceability.